COMMERCIAL BREAK

Weighing in at 900kg and putting over 1000hp through its front wheels, Marius Wehmeier’s home-built Mk2 VR6T couldn’t be a bigger departure from a day job working on classic vans.

Although you won’t find a town more synonymous with Volkswagen than Wolfsburg, you also won’t get far through the company’s history without Hanover making an appearance. Located a little over an hour from HQ, it’s been the hub of Veedub’s van production for almost 70 years – spanning from the T1 Transporter to the ID.Buzz EV – and it’s home to the factory’s ‘Oldtimer’ department, where you can rent a classic bus or have your own restored. And it’s here where you might bump into Marius Wehmeier, though his idea of a re-worked Volkswagen oldtimer is a little quicker off the mark.

“Getting a 12-valve engine over 1000hp was always going to be a challenge,” he tells us, over the chest-pounding hum of idling VR6 a few feet away. “I’ve spent many years implementing new ideas trying to improve the engine and gaining the experience needed to get it right. Building a car to this extent is a life experience, but I wouldn’t change anything – these projects are a work of art that you can feel proud of when they’re done.”

That 17-year process didn’t unfold out of a deep-rooted desire to build one of Europe’s fastest Volkswagens, nor a curiosity to explore the performance potential of one of the earlier platforms. As an 18-year-old, Marius had his sights set on a box-fresh Mk5 Edition 30 GTI but the test drive didn’t measure up to his high expectations. Unsure what to do next, he picked up a white Mk2 Golf CL for €850 as a runaround. It doesn’t take much imagination to figure out what’s happened in the meantime.

“This wasn’t a well-loved classic when I bought it,” he laughs. “The bodywork was bad and there was some rust, so I had it re-painted and that’s also when I started modifying it. It got the big bumpers, a music system then I dropped it on coilovers and new wheels and drove it for three years while I was doing my apprenticeship. My plan was to get a new car when I qualified, but everything was either too expensive or didn’t appeal, so I converted this to a VR6 instead.”

The Golf’s second overhaul was a big one. Marius found the engine on eBay and took on the conversion himself, almost quadrupling the factory power output in the process, and upgraded to G60 brakes with the wider arch trims and Rallye headlights while it was in pieces. The capacity increase had begun a chain reaction. One that led to the Golf getting forced induction and Mk3-spec 5×100 wheel hubs in 2014, followed by a decade of refinements taking that powertrain to where it is now.

That sort of snowballing makes a little more sense when you realise he’s keeping good company. Marius is good mates with Philipp Kaess, the YouTuber and managing director of renowned tuning shop Arlows, which is conveniently located just outside Hanover. It means the Golf has taken shape in an environment motivated by what’s possible, instead of what’s easily achieved. Check out Philipp’s incredible carbon-bodied, B5 Audi RS4 saloon – a project born out the fiery demise of its predecessor – if you’re trying to get a feel for the untethered approach he’s fostered here.

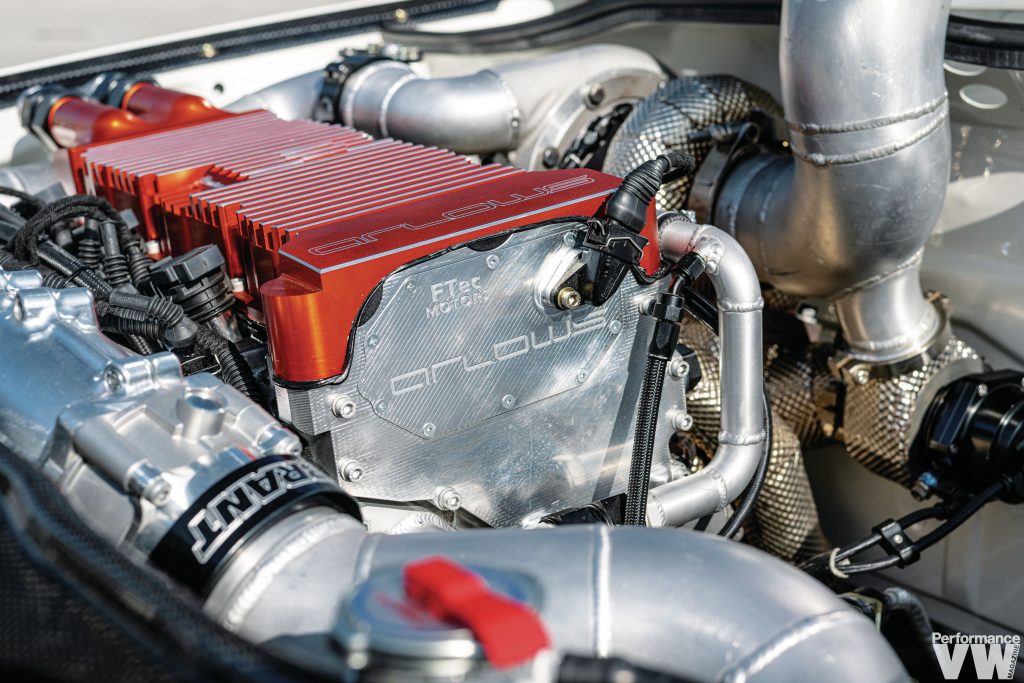

Naturally, the bulk of that effort has been channelled into the Mk2’s front end. The engine is a decade in the making, and as much a feat of engineering as the immaculate presentation suggests. There’s rarely been a fixed spec, but, in its latest guise it displaces 3000cc with the help of a Subi Motorsport machined engine block, stronger Wiseco pistons and Arlows conrods, while the big-valve head was machined by NG Motorsports. It’s built for high revs and even higher levels of boost, packing Dbilas hardware and topped with a custom Arlows-branded JB Motoring valve cover, which improves breathing and functions as a very necessary heatsink.

Although the engine good enough visually to mount on a stand and display, it’s built with function in mind. “You need a good cylinder head and a large turbocharger to get to 1000bhp,” explains Marius. “We’ve had a lot of challenges, with durability, performance, and then building the manifold and cooler package. The mechanical valvetrain allows the engine to withstand higher speeds, and the power is provided by a BorgWarner SX300 converted to a 1200hp charger by TheTurboEngineers. I’ve done most of the work myself, and I’ve learned a lot.”

Of course, he’s brought in the right expertise where needed. The huge turbocharger, now meticulously wrapped in heat-proofing millimetres from the scuttle, required a custom intercooler and Audi R8 V10 throttle body to avoid bottlenecking the resulting boost. That throttle body is mounted onto a short-runner inlet manifold, designed by drag racing guru Don Octane and fitted with 12 injectors to meet its thirst for ethanol, while the screamer pipe chucks still-burning gas vertically through a hole in the bonnet. This isn’t a sleeper.

The important stats? A ferocious 1048hp and 986Nm on the dyno at KKS Performance in 2023, achieved after an all-nighter fine tuning the ECU Master management to wring the final few percentage points out of that hardware. Numbers that big don’t come without some twisted and split mechanical collateral damage along the way, and they’re now focusing a Biblical level of brutality on a tiny contact patch. Yep, it’s still front-wheel drive.

“If I was starting today then I’d choose a Syncro instead, but I didn’t expect to go this far with the project,” he laughs. “It’s got an H Power five-speed dog ‘box with an SQS shifter and locking differential, and the driveshafts are from Adrenalinetuning, so they’ve held up really well. I’ve also had it set up so that the boost is gear-dependent, which means full power is only available in fourth gear.”

Having worked hard for the power, Marius wasn’t willing to let any of that potential go to waste. The boosted powertrain nudged the project towards track use, shedding most of its interior in favour of a Stahlus Racing Cells roll cage roughly ten years ago, before eventually becoming a single seater as the shell was systematically stripped of all except the most mission-critical parts. Even the Rallye headlights didn’t make the cut – they’ve been replaced by 3D-printed lenses with stickers, saving almost 5kg compared to the real thing.

“I wanted to build a chassis that was as light as possible. We were in close contact with H&R, and between us we came up with the idea of building new rear shock absorbers for aluminium to save weight. They’re prototypes, with spring rates specifically adapted to suit my car.”

Despite the Golf’s inherent weight advantages, the 1980s engineering posed problems elsewhere. Even the fastest Mk2s wouldn’t have come close to the 300km/h (186mph) barrier Marius was aiming to break, so it wasn’t a priority when engineers penned its boxy bodywork back 40-plus years ago.

To solve that issue, a custom aluminium spoiler and diffuser keep the featherweight back end pressed against the tarmac at high speeds, and they’re the visible part of an aerodynamic package that’s now in its second generation. It’s completely covered underneath, which helps reduce drag, and gives the airflow an active role supporting the hatch’s lunatic turn of pace.

“It’s built for the racetrack, but mostly for straight-line events,” explains Marius. “The car is very stable at speed and it drives well, but there’s a lot of weight at the front and not much at the back. It’s not really set up for circuits.”

That rabbit hole goes ever deeper. By the end of 2020 – with just shy of 1000hp hauling its featherweight 930kg to a terminal speed of 282km/h (175mph) on a half mile drag – it was clear that there was a need for further refinement to reach the last few goals. Although still fully functional and far from tired visually, Marius pulled the Golf out of service in January 2021 to be torn down, mechanically inspected and to carry out the most thorough overhaul yet. As a trained bodywork technician, he was in his element.

“That was the longest job in the project, it took about six months to do everything,” he tells us. “The entire body was chemically stripped back to bare metal, then I removed a lot of brackets and other unnecessary parts and renewed the seam sealer throughout. It took me three weeks just to sand the interior down, as I wanted it to look as clean as possible, and the shell was cathodic dip-coated for protection before being painted Alpine White again.”

This wasn’t a straight restoration. Elbow deep in interior work, Marius went the extra step of cutting out the spare wheel well and roof, replacing both with carbon fibre panels. They’re from Baltic Carbon (the same place that did Philip’s RS4) and paired with a set of matching wings with a 3cm flare. Not that you’d spot those easily, as they’re body coloured. The home-made Macrolon windows are also only noticeable to the touch, while the Liteglas lightweight windscreen is one of those if-you-know-you-know jobs and edges the Golf under 900kg.

There’s almost no weight left to save. Surviving creature comforts are limited to a layer of Nadelworkz-stitched alcantara, which avoids glare off the dashboard, and the matching foam pads on the carbon fibre Reverie bucket seat, which weighs in at less than 3kg. Tucked underneath each corner are 17-inch MB Design forged magnesium wheels, each saving yet more kilos and wearing some of the hardest-working Toyo R888R track tyres on the planet.

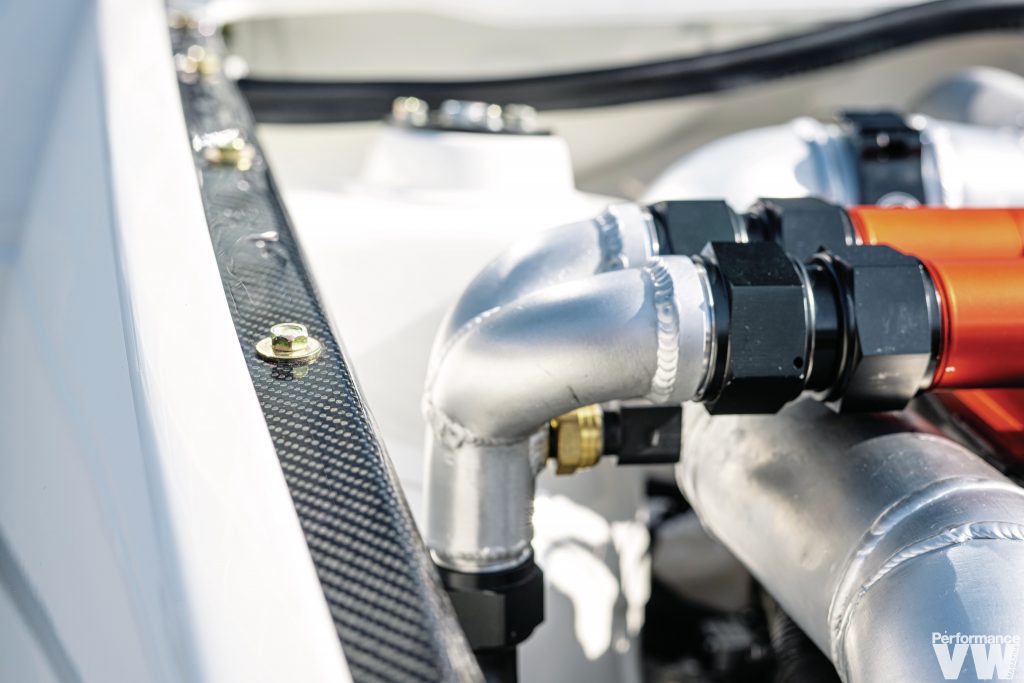

For all the brutality on tap, there’s some impressively subtle OEM+ engineering woven into the build. The dual connectors in the driver’s side indicator fill a custom ethanol tank tucked into the space under the chassis leg and there’s an oil catch can on the opposite side, plumbed into the cam cover. It’s a level of detailing that gets more impressive when you set it against the backdrop of an expanding family, several other project cars and a massive home restoration. That’s a recipe for stopping projects like this in their tracks.

“The Golf has been on the Arlows stand at the Essen Motor Show for many years,” he says. “Even as an unfinished project, the reaction from people was wonderful and very motivating. It’s one of the most exciting parts of the hobby – even though everyone has different ideas and tastes, you meet lots of great people with cool cars. Jean Pierre Kraemer [of JP Performance] had a look at Essen, and he was very enthusiastic about it.”

That hard work has paid off. Freshly rebuilt, re-assembled and dyno tuned to its 1048hp personal best, the Golf put down a 303km/h (188mph) run at the TTT Half Mile event in 2023 having just rolled off the trailer. It managed a further four sprints, topping out at 312km/h (194mph) before retiring with some minor issues to solve. Naturally, Marius hasn’t finished yet.

“I’m thinking about converting it to an R32 engine, possibly with all-wheel drive,” he smiles. “Or maybe I’ll sell it and start again with something new. I’m not sure yet. There are a few cars that appeal to me, like a Golf Rallye, Audi B5 or something like a Porsche 911, but I’ll always have something that’s modified.”

Presumably, whatever follows depends on that all-important test drive to see if it lives up to the hype. In a different world, who knows, maybe we’d be deep-diving a stripped and carbon-bodied Mk5 Edition 30 in these pages – after all, with this level of attention to detail, and some high-profile inspiration, Marius’s first build was never going to be anything run of the mill. It’ll be interesting to see what else he can cook up to cement Hanover’s place in Volkswagen’s history.

DUB DETAILS

|

ENGINE |

3000cc 12-valve VR6, Subi Performance machined block, Arlows conrods, Wiseco pistons, Metal head gasket, CNC machined cylinder head by NG Motorsport, Dbilas mechanical valvetrain and camshafts, JB Motoring CNC machined aluminium valve cover, Custom BK performance self-made manifold, Heat Protect thermal insulation, TTE1200 turbocharger, Audi R8 V10 throttle body, Don Octane intake manifold, custom intercooler and water-cooler made with Tom Wozny Performance, custom boost pipework, in-dash fuel supply by Arlows, 12x Bosch injectors, 4x Arlows fuel pumps, run on ethanol, ECU Master EMU Black with ADU5 display, H Power five-speed dog gearbox with SQS shifter, Don Octane clutch, Adrenalinetuning ADT driveshafts, custom fuel tank refuelled through indicator, custom catch can, Noco 12-volt lithium battery |

|---|---|

|

CHASSIS |

6×17 MB Design MF1 wheels, 205/40 Toyo R888R tyres, Prototype H&R suspension with aluminium rear shock absorbers |

|

EXTERIOR |

Golf CL body, chemically stripped and KTL coated then painted factory L90E Alpine White by Max Kernbach, Baltic Carbon roof, wings and spare wheel cover, Macrolon windows, Liteglas windshield, G60 arch extensions, custom aluminium under-body cover and diffuser, Custom rear spoiler, half-tinted rear lights, plastic headlight with stickers |

|

INTERIOR |

Stripped and re-painted throughout, Stahlus Racing Cells roll cage, Reverie carbon fibre bucket seat, alcantara dashboard and seat pads by Nadelworkz, Beltenick harness, Tilton pedals and balance beam, Momo steering wheel |

|

SHOUTS |

The many companies who have helped, especially my friend Philipp Kaess, who has been supporting me with the project for over 10 years |