FLOORED GENIUS

Laid eight inches lower than stock, Gavin ‘Gavlar’ Dunbavin’s home-built, body-dropped Mk1 Caddy is a feast of fabrication with an air-cooled surprise in the back.

The performance end of the Volkswagen scene owes a lot to being able to mix and match. With a layout that’s barely changed between the Mk1 and Mk8 Golf, owners of the earliest water-cooled cars have gained an ever-expanding choice of (almost) drop-in hardware to bring them up to date. But, while classic styling and modern performance are a match made in heaven, those who want the lowest lows may be better looking further back in the Volkswagen timeline – and things aren’t always as they appear.

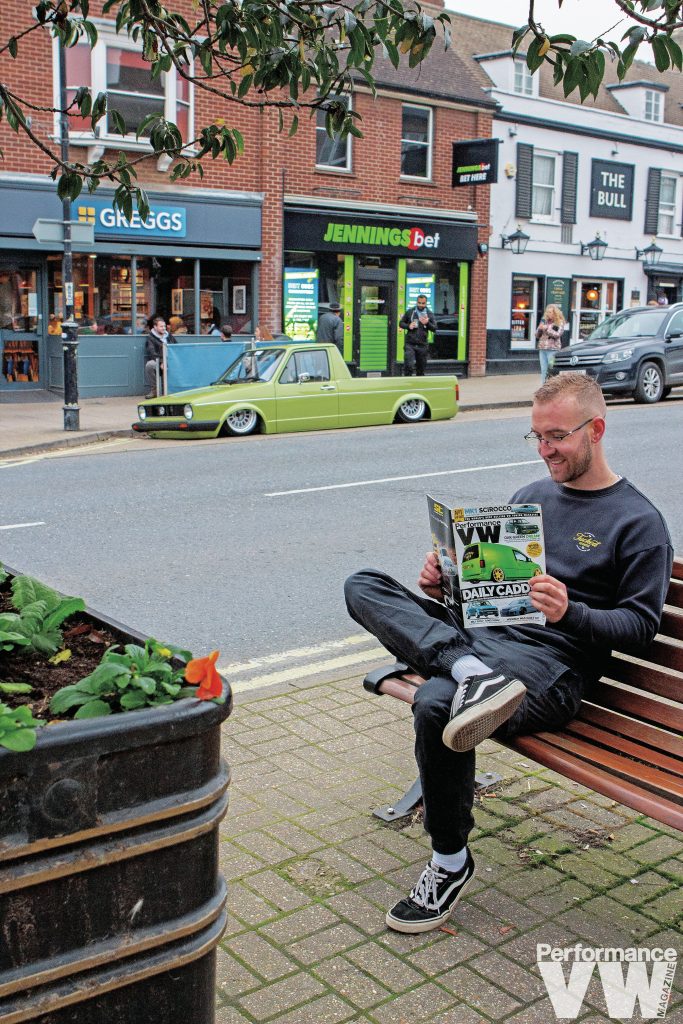

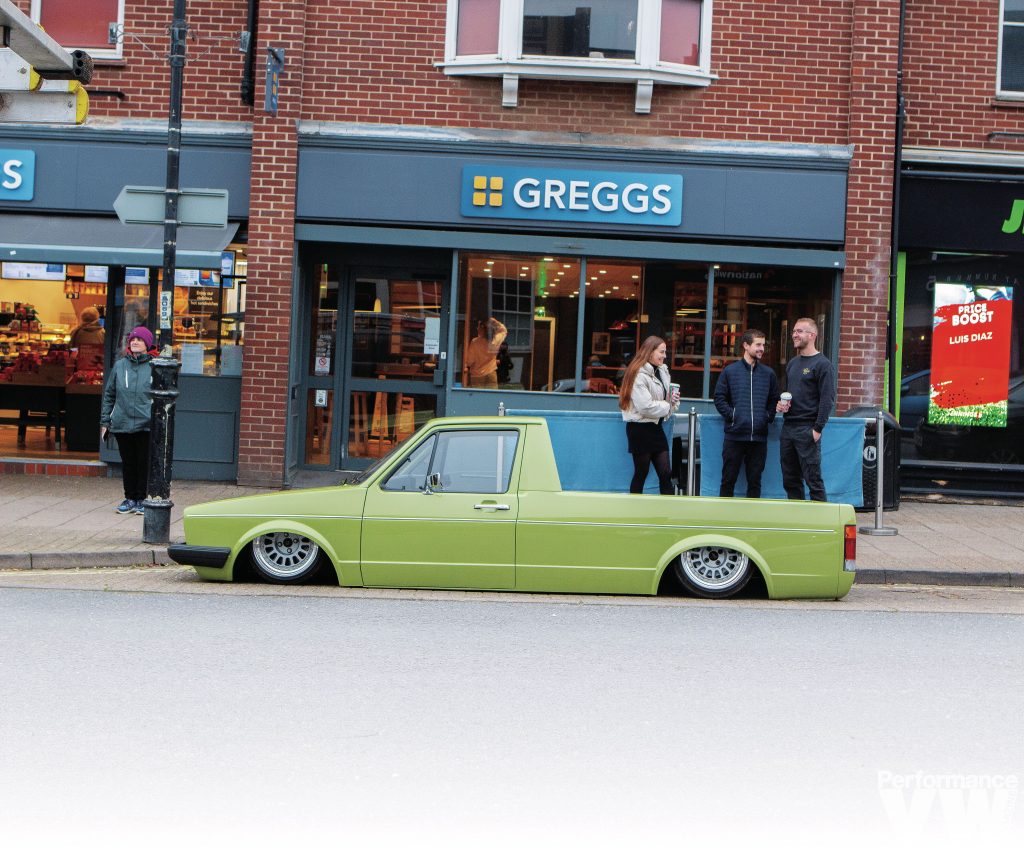

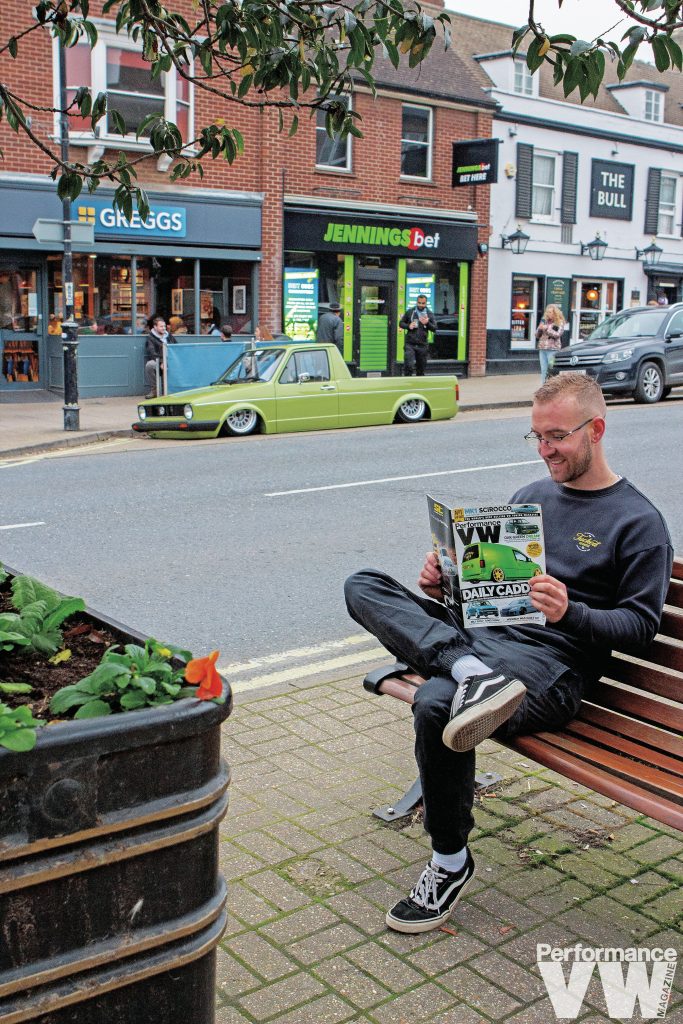

A large reduction in ground clearance rarely fails to grab attention at shows, but Gavin “Gavlar” Dunbavin’s Caddy can stop even the least car-minded high street foot traffic in its tracks. Laid low enough that you’d need to squat to see all four wheel bolts, it has the sort of presence that almost involuntarily draws camera phones from pockets wherever it’s parked, but the best parts of the build lie beneath the surface. After a nine-year DIY rebuild, it’s got more in common with a Beetle than a Golf.

“The only original Caddy parts are the outer panels, everything else has been cut up,” he tells us, calmly tucking into a still-steaming Greggs. “It’s body-dropped eight inches on a Beetle floorpan – the old 16-inch wheels would touch the inner skin of the bonnet when it was aired out. There’s a lot of time and effort gone into this, and I’ve had to work most of it out by myself.”

It probably won’t surprise you to hear this, but this ain’t Gavin’s first rodeo. The Caddy’s overhaul is rooted in a Saturday job as a 14-year-old, restoring, body-dropping and equipping classic cars (mostly Volkswagens) with air and hydros, before going full time after he’d qualified as a mechanic. Old habits die hard. Although he’s now earning a living working on aircraft, most of its garage stablemates haven’t escaped some sort of altitude drop during what became a lengthy build process.

“I bought this car when was 17, as a little project to improve my fabrication and welding skills – there’s no better way to learn on a car than messing up your own,” he laughs. “It was all air-cooled stuff I was working on at the time, so that’s what I wanted too, but they were expensive. Putting a farm truck on the floor seemed like a cool idea.”

We’d be surprised if the previous owner recognised anything other than the number plate. The Caddy had lived most of its life off the beaten track, came fitted with lamping gear (bright lights used to startle wild animals) for shooting out of the bed, and its burgundy bodywork had all the rot, dents and earth-filled cavities you’d expect after decades of farm duty. It was a running, driving truck, but long past the point of becoming a concours-winning restoration.

For Gavin, though, it was perfect. Starting with a rough bodyshell meant there was no need to fret about cutting up a tidy example, and it could do some of the donkey work at the start of the build too. Yes, if you’re wondering, you can get a Beetle floorpan into the back of a Mk1 Caddy – and the right (rust-riddled) donor was a lucky eBay find about an hour from home. Kind of an ironic final haul for the hard-working mini truck.

Of course, there’s no straightforward way to pair a rear-engined platform with the silhouette of a front-engined shell, especially when you’re also factoring a body drop into the mix. The first step was measuring how those two elements compare, before cutting the Beetle floorpan back to its spine (the central tunnel and gearbox mounts) and extending it to fit the Caddy’s wheelbase – which is around 240mm longer.

As the bed is a large part of the truck’s overall length, there was even less flexibility to get this right, as Gavin explains. “I’ve extended mine just behind the handbrake. If you extend the front axle forward then it pushes everything else in the car backwards, and the Caddy doesn’t have as much room as a Mk1 Golf so the handbrake would have been behind the bulkhead and I wouldn’t have been able to move the seat back.

“This way the rear axle moves backwards, the pedals stay in the same place, and everything is in the centre of the cabin next to me. You’ve got to think about this stuff before you start cutting or you’ll make a massive mistake, get it all painted and realise, ‘fuck, I’m not gonna fit in my own car!’”

Everything attached to the spine was fabricated by Gavin to match up with the bodyshell, including bead-rolled floor panels and a compartment behind the rear bulkhead for the fuel tank, battery and other ancillaries. With the engine at the back, the longer wheelbase required an extended gear shifter, clutch and throttle cables, while the pedals were shortened to clear the steering rack – a symptom of the body drop.

It takes a lot of engineering to get a car down this low. The Limebug front beam is eight inches narrower than a stock Beetle item, mounted on custom chassis legs and paired with drop spindles, which effectively lift the mounting point for the wheels higher into the arches. There’s enough clearance up front to get full lock on 16-inch wheels with the Air Lift Performance kit on full drop. As a bonus of the re-designed layout, there was enough space in the Caddy’s original engine bay for the air tank.

Beyond the familiar air-cooled engineering, though, he was flying blind. The Caddy shed around four inches of what had been the sills, and the lower sections were then re-fabricated to bolt onto the chassis – just as a Beetle body would once have been. Most of the metal below the swage lines had to be rebuilt by hand to replace a mix of filler, cracked paint and rust, while the exposed edges of the bed had a lifetime of farm damage to iron back out. Every custom-made element was sympathetically designed to look almost factory fitted – even if you can’t see it without a lift.

“My brother machined me a special tool for my bead roller so that I could make all of the swage lines to the same measurements as the old split screen and bay window campers,” explains Gavin. “All of the swages on the tubs and the one that goes around the top of the buck are the same as Volkswagen used. Most people probably don’t notice – I have had a few say they recognise it – but I know it’s there and my brothers know about it too.”

There’s more to that metalwork than clever styling. With nothing but empty space and steering parts beneath the bonnet, the Caddy has extra vents cut into the inner arches supplying cold air into the tailgate and the new engine bay at the back. Above them, a Type 3 fastback panel with a custom inspection cover offer easy access to the oily bits, and those also took a couple of tries to get right. Having realised that the Type 1 engine would stick up out of the top of the buck, Gavin’s swapped to a rebuilt Type 3 1,600cc with Weber twin 40 carbs and a late Beetle gearbox using shortened axles.

“I wanted it to be simple,” he tells us. “I know Beetles inside out, so I did the same to my car. It means I can fix it easily if it goes wrong. You can lift the whole body off to work on everything without it being in the way. Just unbolt it from the floorpan, disconnect the steering and you’re away. I didn’t skip any corners, I’m a bit of a perfectionist.”

He’s confident in the quality of that fabrication, too. The Caddy rolled into Ultimate Dubs 2019 under a coat of primer, only a few hours after completing an all-nighter with friends to get it back in one piece. It says a lot about a project when, even before it’s been painted, there’s no shortage of people looking to take on the rest of the build.

“I was offered a sum of money for it at Ultimate Dubs, and I was tempted. It would have been a good deposit for a house. But my Mum and Dad reminded me that I’d spent six years doing the metalwork with my brothers, and about all the late nights we’d put into it. I felt bad, so I thought I’d better keep it. I’m glad I did – it’s one of the best things I’ve done, really.”

The upshot of getting the Caddy running was Gavin had a few months to figure out how the truck’s mad mash-up of parts co-existed on the road. It spent summer 2019 getting out to its first events, put in a shift as a wedding car for his brother, then disappeared for the finishing touches. Knocks, bumps and rattles get a lot more difficult (and more expensive) to put right after it’s been through a paint booth – and that’s no DIY job either.

“The only thing I had to fork out for was the paintwork,” he tells us. “I painted the chassis myself, but the body was done at Classic Works. The original plan was to go back to the factory red, but I ended up going with Manila Green instead – I love the colour and Volkswagen used it on the Golf, but not on the Caddy. They’ve done such a good job with it.”

Given the high-street-halting reception behind us, it’s hard to argue with that verdict. That newly painted bodywork is accented with a few carefully chosen chrome trim items and sits even closer to the tarmac than it did on its first outing. The 16-inch 3SDM wheels it was built on recently made way for a set of three-piece, 15-inch Image Billet 60s tucked right up into those bead-rolled wheel arch tubs.

The finish is just as impressive inside, and almost all of it is on display. Gavin kept the original dashboard and Wolfsburg steering wheel, but little else. The brushed aluminium door cards were fabricated by hand using the originals as a template and designed to match to the Kirkey bucket seats either side of the Beetle’s spine. Who needs upholstery anyway?

“Everyone asks what the seats are like to live with,” he laughs. “It’s so low that your legs are flat, like you’re sat on the floor. That’s fine for 20 minutes or half an hour, but anything longer than that and my arse is numb. I might look into the cushions for them, but I’m thinking about changing the seats anyway – I’m not sure I like the big head rests anymore.”

Otherwise, he says, there isn’t much left to do. Having set his mind on keeping the Caddy indefinitely, and with the hard graft out of the way, the next steps are evolution rather than revolution. Despite the extent of the re-engineering involved, it’s surprisingly usable.

“It gets about six and a half inches of lift, which doesn’t sound like a lot, but it’s enough to go over speed bumps and stuff like that comfortably so it’s not too bad. It cruises at like 70-75 quite nicely, to be honest, which is unusual. If it didn’t drive nicely then I wouldn’t be happy with it. It’s got to be right.”

And it is. Mixing and matching air and water-cooled Volkswagens isn’t easy, and it’s rare to find anyone willing to go ten tenths with the conversion. But that nine-year commitment to a floored farm truck shows there’s value in looking further back from time to time. This one really is a match made in heaven

DUB DETAILS

|

ENGINE |

1600cc, air-cooled Type 3, rebuilt and painted gloss black, twin Weber 40 carbs, custom stainless exhaust, 1600cc Beetle gearbox, shortened driveshafts, extended gear selector, clutch and throttle cables |

|

CHASSIS |

8×15” Image Billet 60 three-piece split rims, 165/45 Nankang AS-1 tyres,Beetle ‘spine’ with extended wheelbase and custom floorpan, Limebug 8” narrowed beam, Beetle drop spindles, Beetle disc brakes, Air Lift V2 air suspension, custom air tank |

|

EXTERIOR |

Eight-inch body drop with custom tubs, engine bay and ancillary compartment in the load bed, respray in Mk1 Golf Manila Green, Volkswagen T1 Transporter fuel cap, chrome side trim and door handles, custom tubs front and rear |

|

INTERIOR |

Kirkey aluminium bucket seats, custom brushed aluminium door cards, shortened pedals, aluminium window winders and interior door handles |

|

SHOUTS |

Limebug, VW Heritage, Bugwelder, Caddy Pan, Classic Works |